Order picking is the most resource intensive process in the warehouse. Efficient and accurate picking leads to increased profits and customer service. But how do you know which picking cart to choose for your fulfillment operation? This guide will help!

What is an Order Picking Cart?

Order picking carts are important in warehouse and factory operations. These carts are used to move items from one place to another, improving the accuracy and efficiency of physical inventories and reducing loss due to incorrect counts.

Order picking carts also reduce the need for furniture and stationary workstations.

They can reduce work-related stress and fatigue, promoting a better work environment and improving employee morale. Happy employees are more productive and more likely to stay, reducing the company’s turnover rate and the cost associated with hiring, training new staff, and the transition process.

Types of Stock Picking Carts

Order picking carts are a vital part of every warehouse, distribution center, and 3PL. Choosing a cart is a matter of budget and personal preference, but for daily use, carts should be lightweight, sturdy, with comfortable handholds. Another point to consider is space for necessities such as ziplock bags for small parts, Sharpies, labels, a tablet or clipboard, and a barcode gun. Finally, consider the type and weight of the materials that the carts will have to handle. There are off the shelf or customizable carts for just about every need and type of product.

Let’s look at a few to see what’s on the market.

Security Carts

Made of either coated steel wire or welded steel, security carts assure safe transport of expensive or dangerous items that you do not want just anyone to touch. The cart’s locking system can be a simple padlock or a more secure solution such as a fingerprint reader or chip reader.

Stock Picking Cart

Steel can be a good choice, but resin or steel wire can be a lighter load to push. These carts come in multiple formats and sizes, some with areas to hold a tablet and other items. There are some that even come with a ladder built into one end. Keep in mind that some features increase the weight.

Service Carts

Service carts by Rubbermaid are a standard in a number of food service facilities, but they also make great picking carts! Lightweight, with a number of different sizes and configurations, these carts work best with lighter items.

Utility Carts

These Rubbermaid carts are classic for a reason. They come in a number of configurations and can handle relatively heavy loads. However, the only come with three shelves at most but can be tricked out with bins and caddies.

Smart Carts

Voodoo Robotics makes a wireless, cloud-based Pick-to-Light system that can turn your existing picking carts into smart carts. Forget everything you know about pick-to-light because this system can be used in ways that traditional pick-to-light cannot.

Truck or Platform Carts

These wood, resin, or steel bed carts are for the heavy stuff. Ideally, these are not for lifting heavy things onto. Using a portable hoist, lift, or gantry crane to load the truck is a better idea.

Pallet Trucks

Powered or unpowered, with it without lift, these are workhorses. Pre-palleted goods can be racked and stored then pulled to shipping very easily. However, make sure that you take the weight limits as gospel.

Electric Picking Cart Hybrid

Hybrid electric picking carts, like the Smart Rack 900, allow the picker to stand on a platform and drive a compact cart for efficient order fulfillment and replenishment in narrow aisle environments.

Pack Mule (Electric Towable Carts)

Electric towable carts, also called Pack Mules, have the added benefit of speed and expanded capacity. Pack mules allow for flexible configurations, with multiple carts attached to the electric unit.

Forklifts

These are for the heaviest of heavy loads, and you will need a trained operator to use them. It’s an investment, that’s for sure, but when you are moving a lot of heavy pallets in receiving, shipping, storage, and picking, there’s no better choice.

Types of Non-Electric Batch Picking Carts

Batch picked orders are usually placed in order-specific totes or shipping boxes on the picking cart. Choose larger totes for orders with larger items and orders with multiple items. Small, or single-item orders can be placed into a cart with many smaller totes.

Tall cart with removable totes

Cart with tilted shelves

Cart with built-in totes

Low cart with removable totes

Standard vs Industrial Picking Carts

Standard order picking carts are ideal for operations that need to constantly move small inventory items from location to location (i.e. batch picking). For warehouses that need to move heavier items, an industrial order picking cart is a good choice. Industrial carts are welded using 14 or 12-gauge steel shelves with thick angle posts. The heavy-duty design of these carts guarantees longevity and superior quality compared to standard order picking carts with lighter gauge and wheels.

You can find a wide range of industrial order picking carts in different sizes and configurations. Shelf sizes range from 18″ by 24″ to 36″ by 72″ and load capacities range from 600 to 7000 pounds. Industrial order picking carts are an important part of any facility. Aside from offering transportation solutions, these carts also improve worker efficiency and productivity.

Standard Pick Cart

New vs Used Picking Carts

Although our first instinct is usually to purchase a new equipment, you can find a good deal on pre-owned picking carts. Warehouses and distribution centers come and go, resulting in a steady supply of used picking carts. Used carts are usually in good working order and have sometimes repainted, giving them and almost new feel. Used picking carts often sell for less than half the original price.

Supply chain retailers often sell used inventory along with new while surplus shops sell only used equipment. Heavy-duty, industrial carts tend to outlast their less-sturdy counterparts and are easier to find used. Company X might pay the same price for five standard picking carts as Company Y pays for five used industrial picking carts.

Consider the pro’s and cons of purchasing a used picking cart:

How Much do Picking Carts Cost?

The cost of warehouse picking carts differs based on its size, shelf quantity, and load capacity. Like anything, you get what you pay for.

A simple wire stock picking cart from Wayfair or Amazon might set you back one hundred and fifty to two-hundred dollars while a more robust, industrial picking cart could cost between five and seven hundred dollars.

Purchasing a used cart might allow you to purchase sturdier, longer lasting carts for the same money.

How Technology is Changing Warehouse Picking Carts

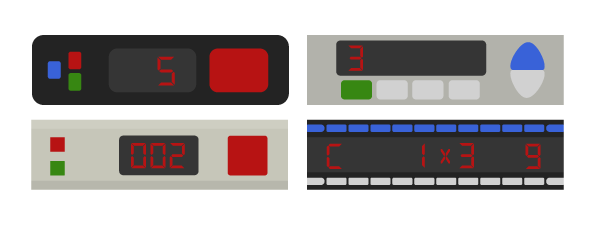

Technology has affected every aspect of society – including the often-archaic equipment used in materials handling and supply chain industries. Picking carts are no exception. Now you can easily find picking carts equipped with platforms for barcode scanners, tablets, and laptops. Perhaps the biggest change is the integration of Pick-to-Light systems with picking carts, allowing for more efficient order fulfillment methodologies, like batch picking to be combined with a boost in pick-rate and reduced errors.

Let’s examine two types of Pick-to-Light systems and how they work with batch picking carts.

Traditional Pick-to-Light

Stock picking carts are increasingly used for pick-to-light operations. Traditional pick-to-light hardware has to be wired to battery powered carts leading to:

Wireless Pick-to-Light

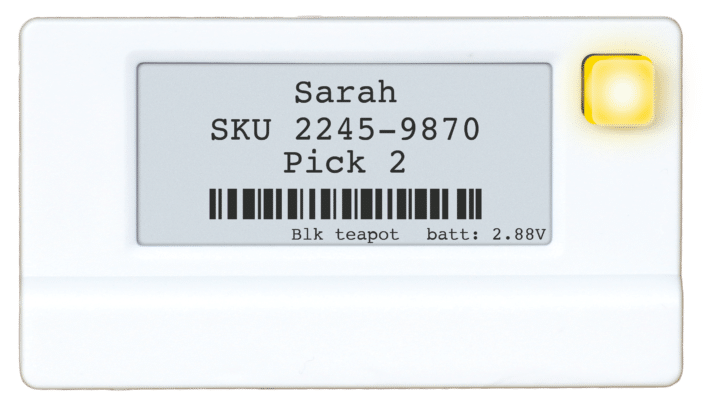

Wireless Cloud Display Devices run on two long-lasting (up to a year or more) AAA batteries and can be mounted almost anywhere – racks, carts, totes, forklifts, etc. They can be used in all sorts of ways – including pick-to-light and put-to-light!

So, forget everything you know about pick-to-light. Forget red and green light bars, forget battery-powered carts, forget limited applications, forget large capital expenses.

Voodoo Robotics reimagined order fulfillment and reinvented order fulfillment by leveraging the latest technology. It’s very affordable and easily integrates with your current WMS, ERP, or even Microsoft Excel.

Now you can:

Voodoo Robotics is revolutionizing order fulfillment with a wireless, cloud-based Pick-to-Light!

Two Ways to Use Smart Carts

Single Lighted System (Put-to-Light):

- The order picker is directed to a stock location.

- (Optional) The picker scans a barcode at that location.

- The picker picks an item from the location.

- The Put-to-Light device on the cart illuminates to show which tote the item should be placed in.

Double Lighted System (Pick-to-Light and Put-to-Light):

- Picker pushes the picking cart down the aisle.

- Pick-to-Light devices associated with a picklist illuminate, indicating what should be picked.

- The picker picks an item from inventory.

- After each pick, the put-light on the cart illuminates to show the tote the item should be placed in.

Get Started

Schedule a demo or contact us to see how easy it is to boost your pick rate and reduce errors by upgrading your current picking carts to smart carts!