Pick-to-Light & Put-to-Light

Frequently Asked Questions

Our Pick-to-Light system easily integrates with your existing ERP or WMS or even Microsoft Office. A simple URL request, sent to our server on the Amazon Cloud, causes the associated Pick-to-Light device to light up with the picker’s name, SKU and quantity to pick!

What is a Pick-to-Light System?

A Pick-to-Light system optimizes warehouse picking and reduces errors by automating the order picking process. Most pick-to-light systems are costly and difficult to install. Our wireless Pick-to-Light solution brings the Industrial Internet of Things (IIoT) to the warehouse with interactive pick-to-light devices that can display:

- Picker’s name

- SKU and quantity of item

- Custom messages

- Barcodes

- QR-Codes

- Icons

- Multiple colors

Our Pick-to-Light system is affordable, mobile, easy to implement, and can be integrated with your current ERP or WMS system.

What is Put-to Light?

Put-to-Light is an additional feature of our Pick-to-Light system which assists pickers or restockers in putting inventory into the correct location (including picking carts and put walls). A simple URL call or REST API call can light up a device to show where the picker should place the inventory.

Examples:

- Batch picking with separate bins

- Put-wall

- Restocking

- Returning canceled orders to original inventory locations.

PTL devices can display:

- Name of restocker

- Item and/or SKU

- Number of items

- Stocking or handling instructions

- Some other custom data

- Hazard icons

- Barcode or QR-Code.

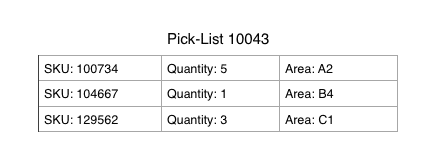

What is a Picklist?

A picklist is a list of items that someone needs to pick from inventory to fulfill an order.

Each picklist line typically contains:

- Product name or SKU number

- Quantity.

Each picklist line can also contain:

- Picture

- Area

- Location

- Dimensions

- Weight.

How much does Pick-to-Light cost?

It is far more economical than you might imagine! Unlike other companies offering Pick-to-Light systems, we are totally upfront about our pricing and will work with you to try to size your project. For example, you may be able to reduce the number of required devices by using light colors and arrows.

Buy a Starter Kit with ten Pick-to-Light devices to see if it boosts your productivity.

Contact us directly for a quote for your system.

Do you offer demo units?

Order a starter kit. It comes with 10 devices and a Turbo. That’s all you need to get a system up and running. After you’re sure the solution is right for you, you can scale up from there.

Does the picker have to press the button to turn the device off?

No. Simply send another ‘completed’ transaction with a one second timeout to turn off a device automatically.

Our Excel spreadsheet demo has an example of this: where a (dynamic) barcode is shown on the device. The picker scans that barcode (to acknowledge the pick), and that scan causes the device to turn off.

Does a Closed Loop System cost more?

There is a one-time fee for registering your feedback protocol prefix. Contact us to find out more.

Components

What components make up the Pick-to-Light system?

When integrated with a typical WMS or ERP, our Pick-to-Light system requires two things:

- Wireless Pick-to-Light devices

- One or more Turbos.

It is easy to integrate the Pick-to-Light system into your own ERP or WMS system and not have to change or adopt a new software. It is as simple as adding URL calls. A REST API is also available.

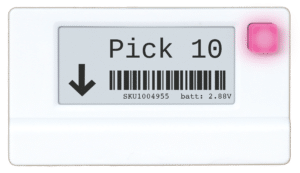

What is a Pick-to-Light Device?

Pick-to-Light devices are modern Internet of Things (IoT) devices that you can use as signposts in your business. They can keep track of the SKUs at a location and/or guide pickers to a destination. Using a simple URL request, devices can use up to five lines of text to display information that is meaningful for your business, such as a picker’s name, the SKU, and quantity to pick. The devices can also use arrows and other icons, six button light colors, play custom tunes, and use an onboard thermometer to read temperature. The devices are wireless, battery powered (very long battery life), and easy to install.

Pick-to-Light devices are modern Internet of Things (IoT) devices that you can use as signposts in your business. They can keep track of the SKUs at a location and/or guide pickers to a destination. Using a simple URL request, devices can use up to five lines of text to display information that is meaningful for your business, such as a picker’s name, the SKU, and quantity to pick. The devices can also use arrows and other icons, six button light colors, play custom tunes, and use an onboard thermometer to read temperature. The devices are wireless, battery powered (very long battery life), and easy to install.

Pick-to-Light devices can easily integrate with an existing ERP or WMS.

What is a Turbo?

Turbos are routers that connect Pick-to-Light devices to the cloud. The Turbos communicate encrypted data using standard HTTPS with the devices and the server.

Pick-to-light (PTL) devices cannot connect to the cloud by themselves – they need the help of a Turbo. The Turbo is the simplest way for the devices to connect to the cloud.

In large warehouses or ones that span multiple rooms, you might need additional Turbos. In busy systems, where multiple requests overlap, adding extra Turbos will decrease response times, making the system faster.

Is there a fixed number of Devices that can talk to a Turbo?

No, but Turbos can get overloaded with 200+ devices around them. In general, we recommend a Turbo for each 50 devices or so.

Are Devices paired to a specific Turbo?

No, devices talk to the nearest Turbo. Handoffs are all automatic, and the customer does not need to deal with these intricacies.

How far can Devices be from Turbos and still communicate?

Devices can communicate 75 feet or even more, but we recommend placement of Turbos every 50 feet or so to make sure communications are rock-solid.

What are the Device dimensions?

Modern devices are approximately 5” wide x 3” height x 0.6” depth (excluding button).

How many colors does a Modern Device support?

Six individual colors.

To conserve battery power you should use the colors red, green and blue instead of cyan, magenta, and yellow. The latter colors actually use twice as much power as the former.

On which cloud are you running your server?

We use Amazon Web Services (AWS). Generally machines running on the Amazon cloud are far more secure than machines running on your LAN behind your firewall!

Details

How long does it take for the Pick-to-Light device to light-up?

A single Pick-to-Light device should respond to a URL request in less than a couple of seconds (usually about 9/10 of a second).

A typical picklist with five items will generate five URL requests and light up five Pick-to-Light devices in approximately ten seconds (the first after two seconds, and the last after about ten seconds). Adding additional Turbos can reduce the time.

Do lights light up instantaneously?

No! Unlike some wired systems, wireless devices, spend most of their life sleeping to preserve battery life. It takes a couple of seconds for API request to process through the system. BTW, the latency is largely between the Turbo and the device, so faster routers, higher Internet speeds, etc., will likely have little or no effect.

Can I speed up my communications?

You can make marginal improvements in latencies by using extra Turbos. See Trevor Blumenau, CEO of Voodoo Robotics discuss this:

Can devices display default information?

One important feature of Cloud Display Devices is that they can display or retain what we call ‘static information’, information that the device displays when it is inactive. On our Cloud Display Devices with an E Ink display, this information always displays on the device.

You can set this information using the QueryString or REST APIs, or you can set the information directly using your www.sku-keeper.com or Big Block Server account.

If you are using devices to identify inventory, you probably will want to store the name, SKU and quantity available of that inventory.

If you are using devices to track a customer’s order, you will probably want to store the Order ID, shipping carrier, number of lines of the order, etc.

How long do the batteries last?

The Pick-to-Light devices have been designed to maximize battery efficiency. PTL devices spend most of the time “sleeping”.

With typical use, the two AAA batteries could last years. It really depends on how frequently you activate the device.

Is there a low-battery warning?

The system continuously monitors the battery voltage of each device.

The device itself always displays the current battery voltage or a low-battery warning. On Big Block server, you can easily get a list of locations with Pick-to-Light devices that have battery levels below a cut-off value that you specify.

How do you change the batteries?

Battery changes are quick and easy. Batteries are accessible from the bottom of the device, without the need for dismount. Do not worry, after a battery change, devices come right back to where they were before the battery change.

How do I know if a line was actually picked?

On Modern devices, we recommend using a dynamic barcode for acknowledgements:

The picker scans a specially constructed barcode (perhaps with Order-ID and line number embedded) on the device to acknowledge the pick. That scan can also turn off the light, so that the picker does not have to push the button.

How do I check all my batteries?

There are two ways to check all your batteries at once:

- On Big Block Server, you can rank All Devices by battery voltage, or on the Problem Devices page you can list those devices with battery voltages below a certain threshold.

- Using the REST API, you can first get a list of all devices in your account, and then run a query for the voltage of each device.

What is this about a ‘Prefix’ for a Closed Loop System?

The prefix is the beginning part of a URL that you provide to Voodoo. We enter that into our system and when we send an acknowledgement, we simply append the ack/nack to the prefix (along with a transaction ID that you choose).

More Details

What are the components of the QueryString URL?

Check out our detailed discussion of each part of the QueryString. We also have a REST API.

Where is the REST API documentation?

Check out our documentation along with an example in PHP.

How do I control the layout on the display screen?

The layout is automatic. The largest text is used for the total number of lines and characters that you choose. QR-Codes, when specified, are always placed in the top left corner. Icons, when specified, are placed in the bottom left corner, but move to the top left corner if no QR-Code is present. Barcodes, if specified, display along the bottom.

For more information, check out our encoding rules.

Can I make multiple API requests at once?

Absolutely, that is the way the system is designed. For example, after scanning a picklist, send a URL for each line in the list. If you want a particular item to light up first, you might want to send that one, followed by a 100ms delay, and then the others.

Installation

What are the requirements?

The easiest way to connect the Pick-to-Light devices to the Internet is to install one or more Turbos. Turbo installation is typically high on a wall or ceiling and can connect directly over Ethernet (DHCP) to your LAN. If you already have WiFi in your warehouse, you can connect to the Turbo to your WiFi network.

Pick-to-Light devices work with any ERP or WMS solution, or even Microsoft Office. A simple URL is all it takes to activate a device. You can also use our REST API.

Where can Pick-to-Light devices be mounted?

Pick-to-Light devices can be mounted to picking carts, boxes, bins, containers, shelving, pallet racking, put-walls, and more. You can mount a device just about anywhere!

How do I attach the Pick-to-Light devices to my warehouse locations?

If not using the magnets on the ruggedized case, the second most popular method is outdoor double-sided tape. You can also use velcro, screws, bolts, zip ties, wire, string, twine or whatever you most feel comfortable using.

Can I put Pick-to-Light devices in shipping and receiving bays?

Absolutely! Mount Pick-to-Light devices wherever you want to keep track of inventory and products coming in and going out. The PTL devices will help you find and keep an accurate count of what is on hand 24/7.

Where should Turbos be mounted?

The general advice is to mount Turbos above 8 feet on racks or walls with a good (not necessarily perfect) line of site to devices. The 8 foot guideline gets most customers above the general foot traffic in the warehouse. Turbos can be mounted to ceilings, but some ceilings in warehouses are very high making the distance between the Turbo and devices is too large.

Integration

Can the pick-to-light devices integrate with my current ERP or WMS?

Pick-to-Light devices can easily integrate with any ERP or WMS system. The simplest way is to intercept the barcode scan at the beginning of a picklist and create a URL for each line of the pick list.

What else can I do with the pick-to-light devices?

The only limit is your imagination! The devices can light up and display any message you would like. We challenge you to come up with new ways to use them in your operations.

Do you recommend using Excel or Google Sheets?

We do not recommend using Google Sheets because of the inconsist latencies between API calls. Essentially Google Sheets runs on Google cloud servers that do not have consistent latency performance.

Microsoft Excel, on the other hand, runs directly on the client and shows consistent low latency.

BUT for large operations with existing WMS or ERP systems, we strongly urge you to integrate directly with your WMS or ERP. Exporting data from your WMS to an Excel spreadsheet for use by pickers, while it may look like a good option, can create data inconsistencies and be difficult to maintain.

The Demonstration Spreadsheet applications that we distribute (in Excel and Google Sheets) are for demonstration only and should not be considered solutions in themselves!